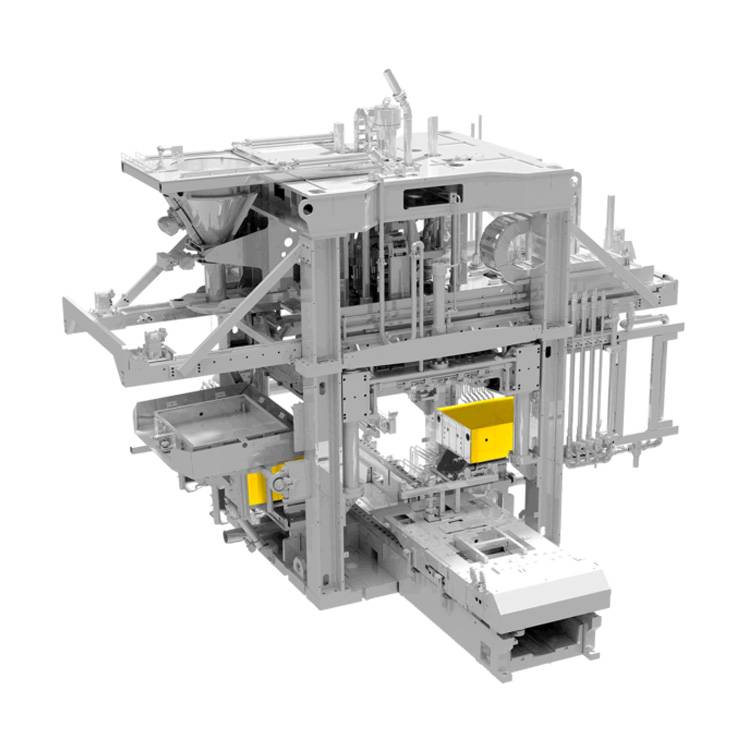

product Description

Bottle sizes with a capacity of less than 0.3L can correspond, with 24 to 48 cavities. Up to 48 cavities can be opened.

Use three rows of mold cavities to increase production capacity, suitable for packaging bottles with small capacity and high production capacity.

Application: Used in various food and non-food bottle types, cosmetic bottles, alcohol, beverages, oral liquid bottles, medicinal bottles, etc.

Applicable materials: PET,PETG, PP,PC,PLA,PEN,PS,PES,RPET, etc.

Available shapes: round, oval, non-round, ultra-light, shaped bottles, etc.

PET can correspond to zero-cooling technology.

The advantage of the four-station method is that there is a separate temperature adjustment station, which can better adjust the temperature of each section of the preform and form various complex styles of bottles. The preform molds for the same bottle mouth can be used universally, and can be blown big and small to make bottles of different shapes. Save investment costs for injection molds.

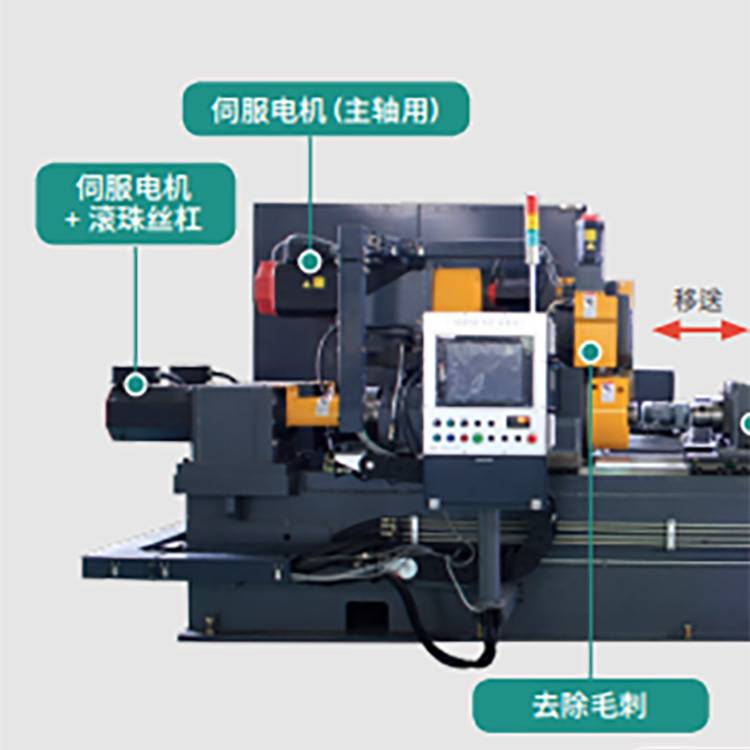

product parameters

| Summary of machine specifications | units | ASB-150DPX |

| Standard injection molding unit/screw diameter | Type/mm | IU-111/84 |

| Choice of screw diameters | mm | 75/95 |

| Theoretical injection molding capacity | cm3 | 1330 |

| Injection molding clamping force | KN | 1472 |

| blow molding and clamping force | KN | 653 |

| Driving power rating | KW | 87.5 |

| Rated total heater power | KW | 124.7 |

| mailbox capacity | L | 1000 |

| Machine external size (L X W X H) | mm | 7773X2810X4390 |

| Machine quality (approximately) | kg | 27000 |

Messages

Messages