product parameters

| parameter name | numerical range | Description (optional) |

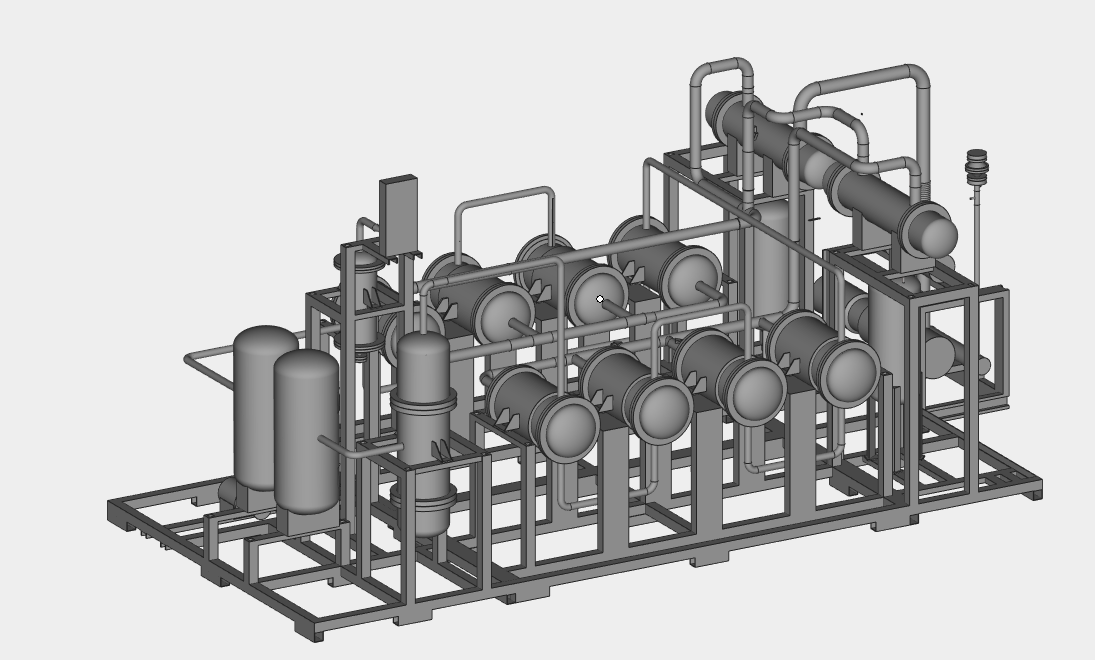

| heat exchange area | 0.3~7㎡ | Please inquire in detail for specific customer needs |

product Description

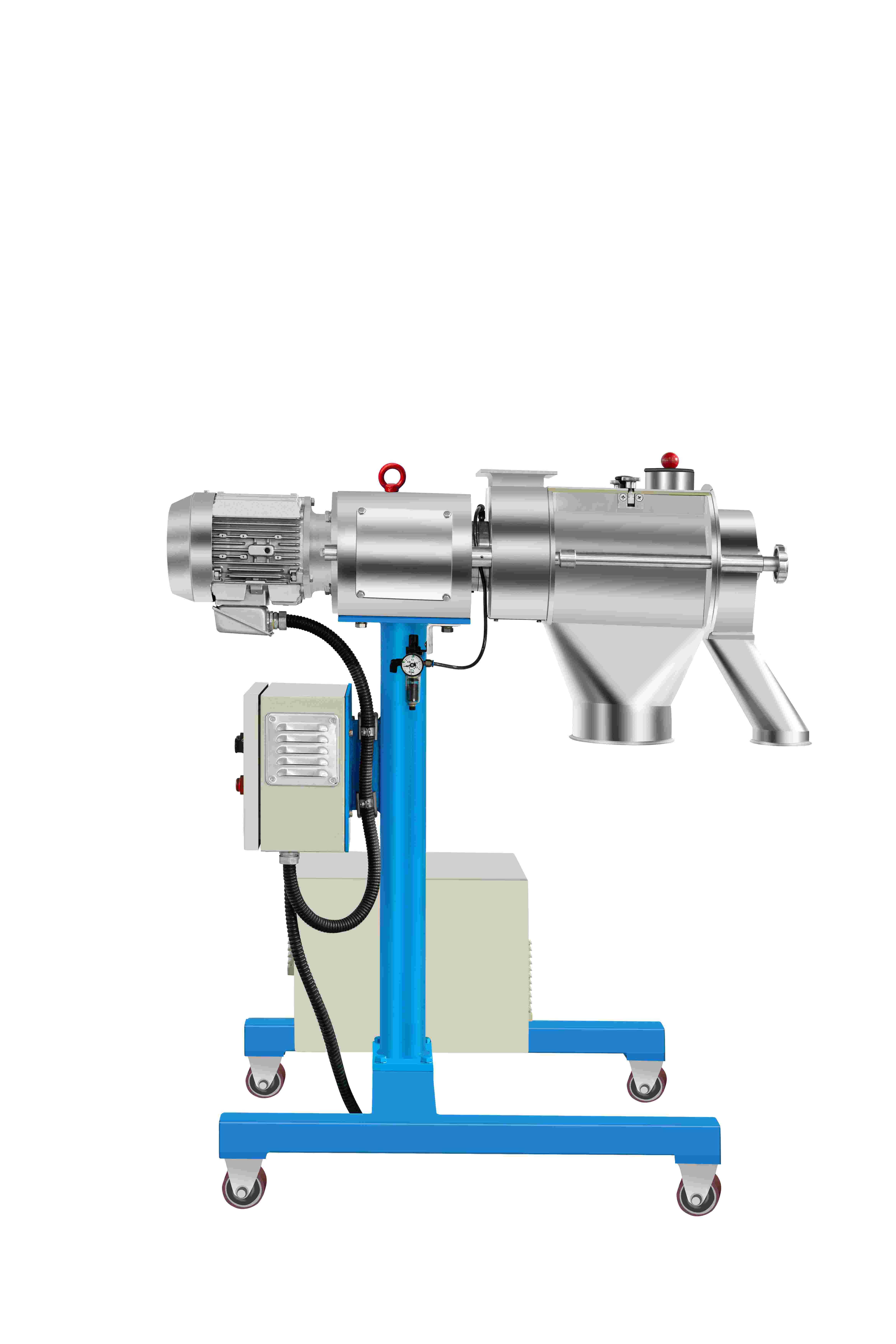

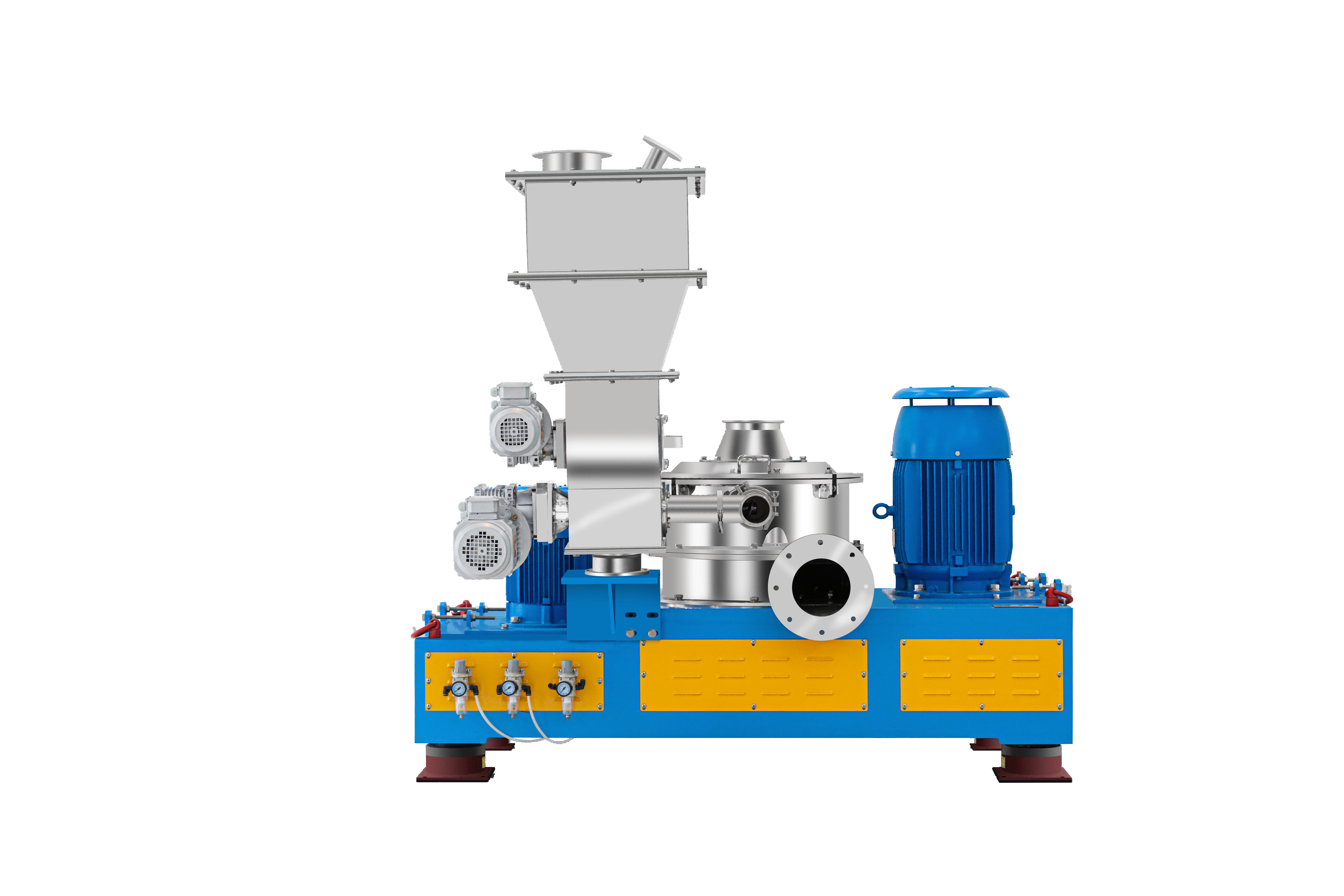

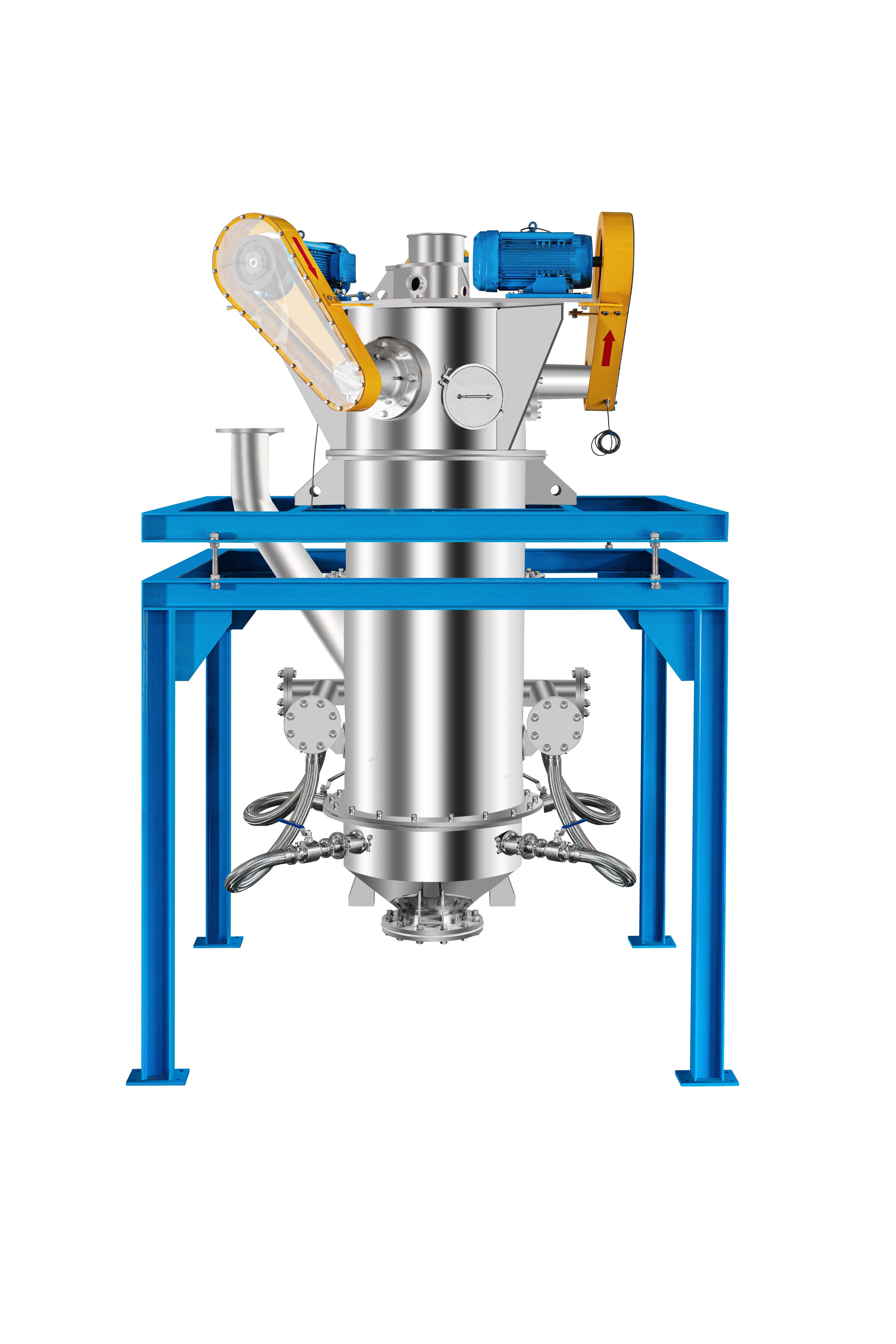

Many prepared foods and other products do not achieve optimal heat transfer due to their consistency. For example, large, sticky, sticky and crystalline products contained in foods can quickly block or clog certain parts of the heat exchanger. The scraper-blade heat exchanger adopts special designs that can well heat and cool products that affect the heat transfer effect, making it a model heat exchanger. When the product is pumped into the material barrel, the scraper frame and scraper device ensure even temperature distribution, and scrape the material away from the heat exchange surface while continuously and gently mixing the product. Terlotherm is a vertical scraper heat exchanger equipped with two coaxial heat exchange surfaces to provide optimal heat exchange. This design and other product features provide you with the following benefits:

The vertical unit provides a large heat exchange area and saves valuable production floors and area in the workshop. The largest equipment heat exchange area can reach seven times that of traditional equipment;

Single mechanical seal. All other equipment is equipped with a minimum of two mechanical seals and takes a long time to replace. Terlotherm's mechanical seals can be quickly replaced. There is no need to use hydraulic systems like other traditional equipment;

Simple and easy internal inspection of the equipment, the top cover on the top of the equipment can be opened without the help of tools. No need to remove seals and shafts;

Easy to maintain, easy to disassemble, and simple to clean;

All parts in contact with materials are FDA approved materials;

The heat exchange surface shall not be made of potentially dangerous materials, such as chromium or other materials. Equipped with reliable high-quality stainless steel to avoid danger or contamination of the product;

Terlotherm operation takes advantage of low pressure and low speed, but still maintains the same blade end speed as other higher-pressure and higher-speed equipment. This is due to the unique design of the double-layered material cylinder. This is the * important advantage when dealing with highly sensitive or complex products that are susceptible to damage by high pressures and high rotational speeds;

With modular design, heat exchange capacity can be increased by replacing the material barrel without replacing complete equipment;

Efficient heat transfer is achieved through continuous scraping of the entire heat exchange surface;

Terlotherm has obtained USDA, U-Stamp, ASME and China Special Equipment Manufacturing (Pressure Vessels)**;

Scraping blades and sealing rings that can be detected by X-rays and gold detectors provide greater food safety.

Messages

Messages