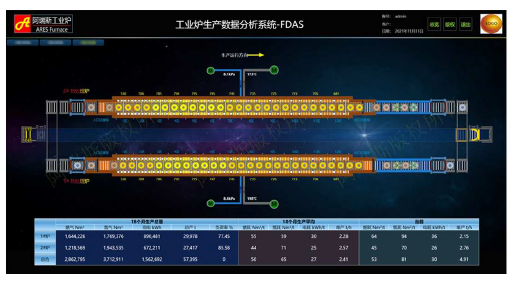

为了适应企业的数字化,信息化和智能化建设需求,针对企业内部设备管理方面存在的问题,我们推出一套工业炉设备智能管理系统,以帮助企业更好解决设备运行、产品质量、能源消耗、设备维护以及工艺设定等问题,达到更好利用设备和生产效率,同时降低生产成本。

ln order to meet the needs of digital, information and intelligent construction of enterprises, aiming at the problems existing in the internal equipment management of enterprises, We have launched a set of industrial equipment intelligent management system to help enterprises better solve the problems of equipment operation,product quality, energy consumption, equipment maintenance and process setting, so as to make better use of equipment, lmprove work efficiency and production efficiency, while reducing production costs.

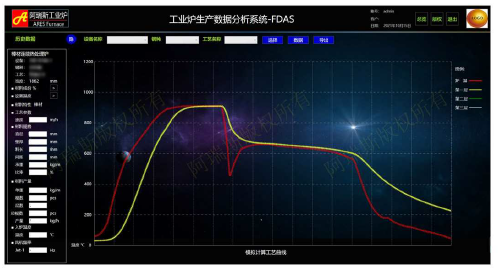

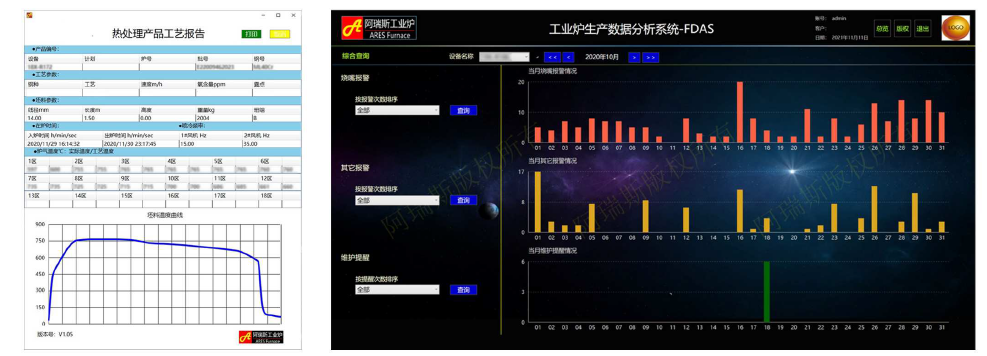

软件特点:

关注单一生产设备,实时感知工业炉设备的工况数据、生产数据等信息,对工业炉设备运行情况进行详尽统计和分析,为企业提供预测以及计划参考,从而提高设备的有效利用率和生产效率,让数据驱动效益增长。

软件模块:

综合分析

实时监控

能源消耗

生产汇总

设备维护

生产工艺

Software features

Pay attention to a single production equipment, sense the working condition data, production data and other information of the equipment in real time, make detailed statistics and Analysis on the operation of the equipment, and provide prediction and strategic reference for enterprises, so as to improve the effective utilization and production efficiency of the equipment and make the data-driven business growth.

Software modules:

Comprehensive analysis

real-time monitoring

energy consumption

production summary

equipment maintenance

production process.

消息

消息