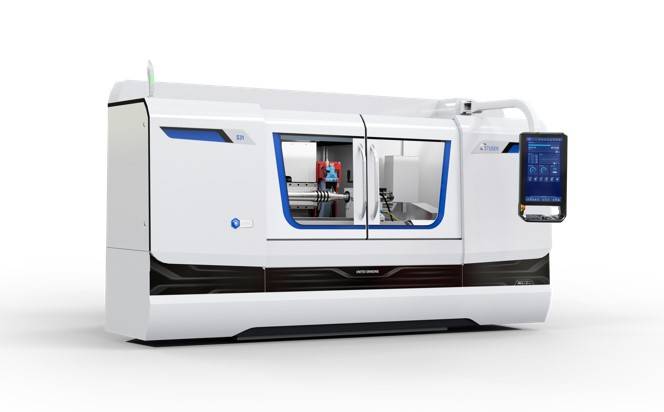

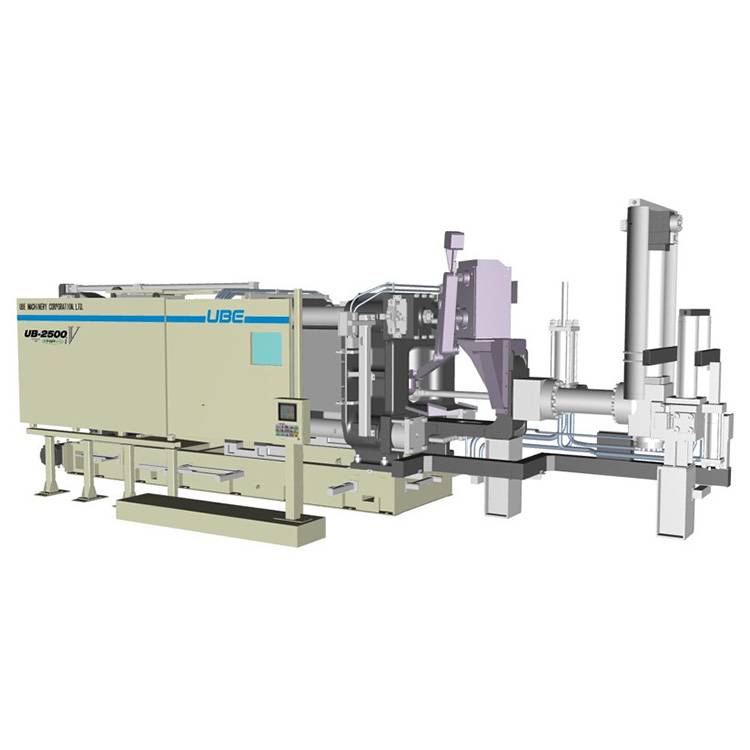

阿瑞斯工业炉开发的辑底式机械零件连续热处理线,主要用于机械行业批量较大的板件类高强或耐磨零部件的调质热处理。针对不同的工件,采用不同的炉辑形式,不同的传动控制方式,不同的淬火方式;以满足不同工件对淬火、回火和控制冷却的各种工艺要求,最终达到零部件对产品性能和外形公差的要求。

全自动化物流输送:

该处理线是将淬火加热、淬火、回火、控制冷却等多种工艺集成的全自动、高精度的连续调质热处理线。该热处理线采用辑底式物料传输,实现全程物料跟踪,并且可实现自动组织物料(分料或成批)。

多样的淬火方式:

根据不同的版型,可以选用不同的淬火方式,实现均匀冷却,从而能够很好地保证机械性能的均匀性,以及物料平面度。

高效的加热方式:

加热系统采用德国进口自身预热烧嘴,具有加热效率高、温度均匀性好的优点。回火炉配以大流量炉气内循环系统,达到很高的温度均匀性要求。

Roller hearth heat-treatment line for work-pieces developed by ARES is mainly used for quenching and tempering heat treatment of high-strength or wear-resistant work-pieces of plate with large output in mechanical industry.For different work-pieces, using different rollers, different transmission control mode and different quenching mode to meet the various process requirements of quenching, tempering and cooling, and finally achieve the requirements of product performance and shape tolerance of work-pieces.

Fully automatic logistics transportation:

lt is a continuous heat-treatment line with fully automatic and high precision integrating various processes such as heating, quenching,tempering and controlled cooling.The heat treatment line realizes the automatic material tracking and automatic material distribution of the whole process.

Various quenching methods:

According to the shapes of the work-pieces, different quenching method sare used to achieve uniformity of cooling, so as to ensure the uniformityof mechanical properties, as well the flatness.

Efficient heating method:

The heating system adopts high quality preheating burner system, which has the advantages of high energy efficiency and good temperature uniformity.The tempering furnace is equipped with the large gas flow circulation system to achieve high temperature uniformity.

消息

消息