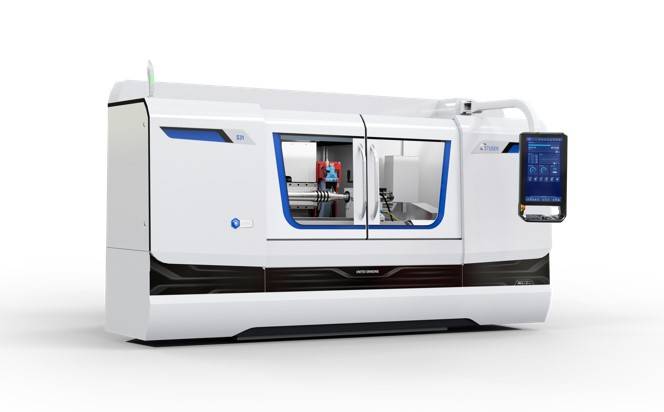

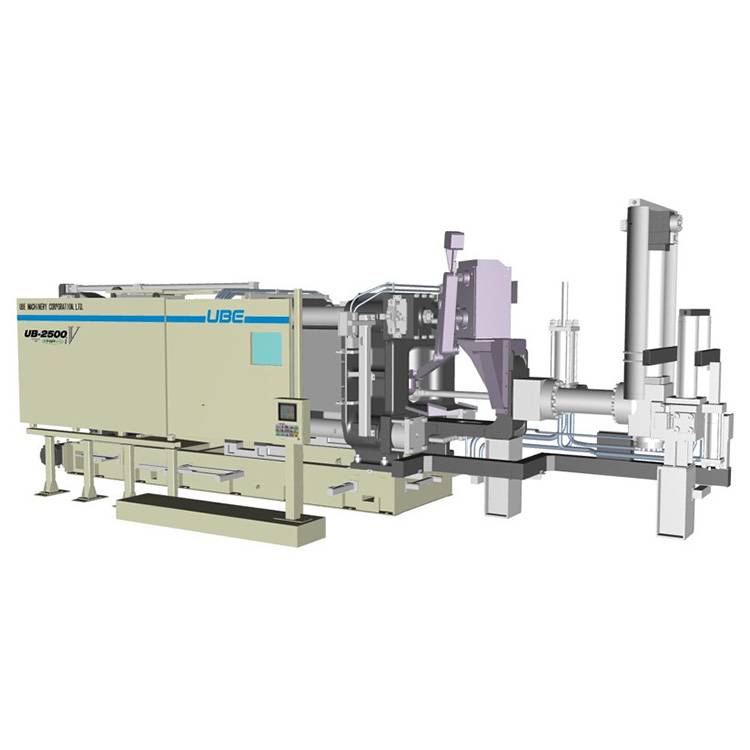

阿瑞斯首创的VRL-L辑底式大直径管棒连续调质热处理线,适用于直径为80-400mm合工钢、合结钢、镍铬钢等大直径厚壁管材、棒材的连续调质、正火、退火、固溶等热处理。针对不同的热处理工艺要求, VRL生产线可有不同的设备组合。

VRL-L series heat-treatment line is designed for large diameteralloy structural sttel bars and pipes ( 80-400mm ) continuousquenching and tempering, normalizing and stainless steelsolution heat-treatment process by ARES. According to different heat treatment process requirements, VRL production line can have different equipment combination.

VRL-L热处理线加热炉采用V形斜辑,具有热校直功能,在高温下通过炉辑对处理材料的约束,可在加热过程改善原材料的直线度。采用自身预热烧嘴加热系统,炉温控制精确。

淬火机采用环形风/水环,处理材料实现360°强力均匀冷却,确保材料淬火深度和直线度,减少校直工序。

根据需求,回火热处理炉可配置V形斜辑或平直辑,回火炉后配置有冷却装置,以避免材料出现回火脆性。

VRL-L系列热处理线还可配置“阿瑞斯RDMS-热处理线远程服务系统系统”、“FDAS-工业炉生产数据智能分析系统”。

The heating fumace of VRL-L heat treatment line adopts V-shaped inclined roller, which has heat straightening function. Under high temperature, the straightness of raw material can be improved through the restriction of furnace roller to the processed material. Recuperative burner heating system is adopted and furnace temperature control is accurate.The quenching machine adopts annular air / water ring to realize 360 ° strong and uniform cooling of the treated materials, ensuringthe quenching depth and straightness after material treatment,and reducing straightening process.

According to the demand, the tempering heat treatment furnace can be equipped with V-shaped inclined roller or flat roller, and the cooling device is equipped behind the tempering furnace to avoid temper brittleness.

消息

消息