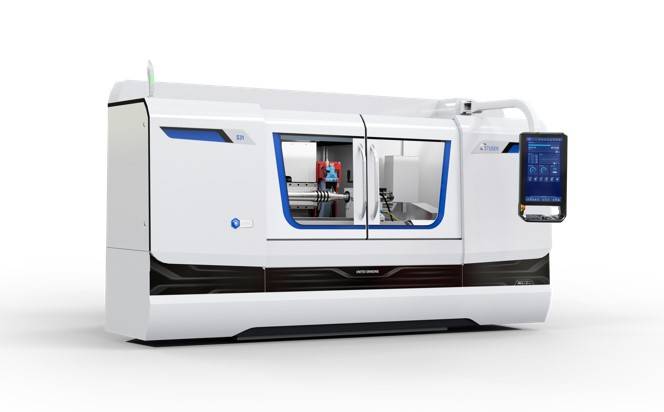

WRF辑底式保护气氛线材连续热处理线,适用于轴承钢、冷暾钢、弹簧钢、合结钢线材盘卷的球化退火、软化退火等多种热处理工艺。

WRF系列热处理线采用氮气保护,自身预热烧嘴辐射管配合高温循环离心风机和炉内导风系统的强对流间接加热。物料在热处理过程中加热、冷却均匀。热处理后物料表面光洁、微脱碳;有效避免后续拉丝过程中出现表面裂纹。根据工艺需要和物料规格特点,WRF配置真空锁气室和自动装卸卷设备。

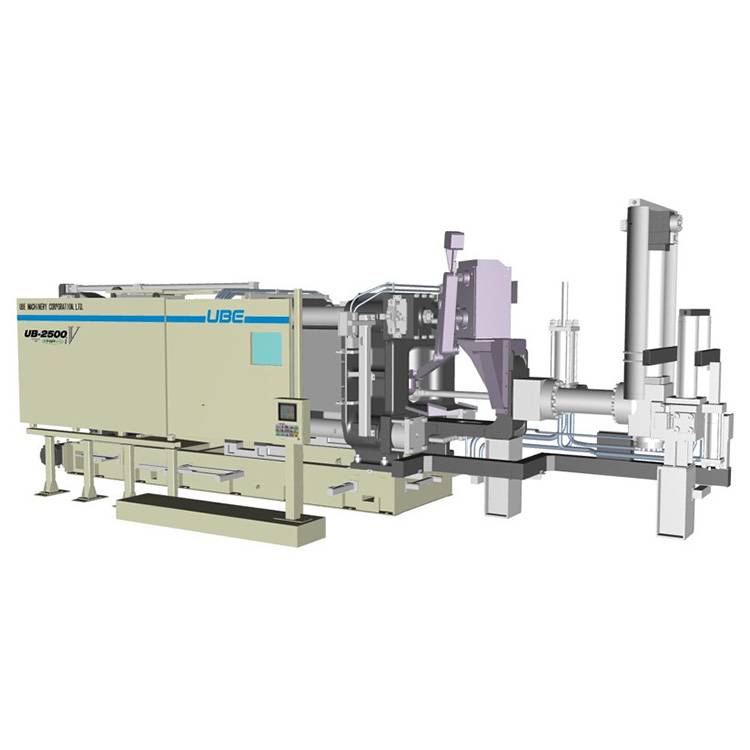

WRF series heat-treatment line is designed for wire coil multifarious heat-treatment process by ARES. The material of wires include of bearing steel, cold heading steel etc. Various process can be fulfilled in WRF, such as spheroidizing annealing, soft annealing.

WRF series heat treatment line adopts nitrogen protective atmosphere, Recuperative burner, radiation tube, high temperature circulation centrifugal fan and strong convection indirect heating of furnace airguide system. In the process of heat treatment, the material is heated and cooled evenly. After heat treatment, the surface of the materialis smooth, which can realize micro decarburization, and effectively avoid the possibility of surface cracks in the subsequent drawing process. According to process requirements and material specifications, WRF is equipped with vacuum lock chamber and automatic coil loading and unloading equipment.

根据需求,WRF系列热处理线可配置“阿瑞斯RDMS-热处理线远程服务系统系统”、“FDAS-工业炉生产数据智能分析系统”。上述技术的使用,可大大提高产品质量的可追溯性和热处理工艺的开发水平。

ARES Intelligent Control System has been used on WRF series heat treatment line and configured with " RDMS- heat treatment line remote service system", "FDAS- industrial furnace production data intelligent analysis system" . The use of the above technology can greatly improve the stability of product quality,improve the efficiency of equipment and reduce the production cost.

消息

消息